How airports can tackle their biggest lighting challenges in 2022

With passenger volumes continuing to make a steady recovery, many in the airport industry will be starting to look forward to what will hopefully be a better year ahead.

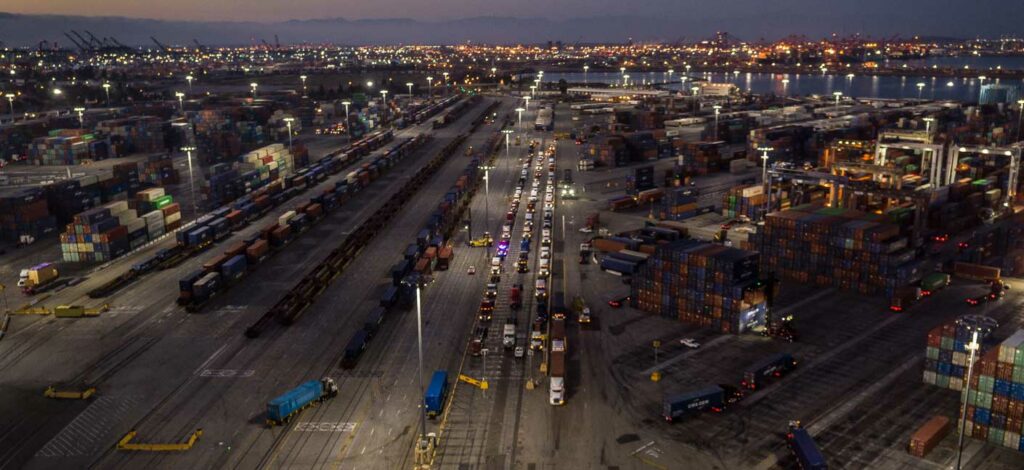

While it might not be at the very top of the priority list, apron lighting will undoubtedly be an area of focus for some. As sustainability initiatives become more widespread, and airports continue to look for ways to rebalance costs following a disruptive few years, a fresh approach to lighting offers the chance to make significant progress in both areas at once.

For those who do want to look again at their lighting, one of the first challenges they may face will be in ascertaining how effective their current setup is. The situation might be much better than it was 10 years ago, but many airports still don’t have a clear view of the quality of their existing lighting system. Surveys tend to be conducted relatively infrequently, and the complexity involved means that even when they are, the results don’t always provide an accurate reflection.

That’s a significant problem, because it leaves airports without a clear idea as to whether their lighting setup conforms with ICAO and EASA/FAA standards. Though that might not result in a fine, as it could in other sectors, it does mean that non-compliant stands will end up being limited to use during daylight hours only – something that can be hugely damaging in terms of operational efficiency.

A quick guide to apron lighting

One thing that may help here is Midstream’s own Photometric Measurement guide. It doesn’t avoid the need for airports to undergo a lighting audit, but this free document does provide a step-by-step process which they can follow to test their compliance.

Tackling the infrastructure gap

For those airports that do want to improve the quality of their apron lighting, retrofit solutions can be a cost-effective option. But these too can pose their own challenges, particularly when mast infrastructure hasn’t kept pace with expansion elsewhere.

At many airports, the original lighting masts will have been installed during the 1970s or 1980s. A few may have been added along the way, but usually at a slower rate than new stands. It’s therefore not uncommon for an airport that had three masts and five stands in 1980 to now have six masts split across 15 stands, for instance.

That kind of disparity makes compliance very difficult. New regulations state that every stand now requires lighting from two different directions, something that is mathematically impossible in a scenario like the one described above. Rome Fiumicino provides a great example of what is actually needed in a situation like this; a complete overhaul of the mast infrastructure, resulting in an incredibly well-lit airport and huge energy savings in the process.

While reducing the amount of energy used is obviously helpful from a budgetary perspective, innovations in mast technology can also have a major impact on cost. Midstream’s Modus R1000, for instance, utilises a lightweight luminaire and a series of high-performance, asymmetric optic lenses. This, combined with a remote driver configuration, means that the height of the mast can be vastly reduced – resulting in a cost saving of around 70% over traditional models.

Time to act?

While passenger volumes have shown a strong recovery over recent months, they remain low in comparison to pre-pandemic years. As a result, it can be tempting to assume that apron lighting is something that airports can push further down the to-do list. For those who want to improve their bottom line, however, that isn’t really the case.

In our own experiences, many of the airports that have invested in a new lighting system over the past two years have saved a considerable amount of energy by doing so. While airports locked into old sodium-based systems have needed to leave apron lighting running no matter how many flights are departing, those with LED solutions have been able to power them on and off as needed. With the maintenance costs on those old systems also continuing to increase, waiting for business as usual to resume can actually be a false economy.

The payback time on new systems is also getting shorter by the day. Whether it’s a retrofit solution or a completely new installation, an LED lighting system typically starts to deliver a return on investment within two to five years. Even making the switch from first-generation (c. 2011) LED floodlights to next generation ones can offer significant savings.

The main priority, of course, is to get the advice of a company that specialises in the very specific requirements of modern apron lighting. As well as manufacturing our own series of award-winning aviation floodlight solutions, Midstream also offers a complimentary design and consultancy service covering everything from light levels to wingtip clearance.